What You Should Know About Lubricating Plastic Threads

Even though our plastic components don't require any external lubricants, people still want to know if they can use WD-40 or another lubricant on them.

This article is intended to emphasize that absolutely no lubrication is required for our lead screw nuts; however, you can still use the WD-40 or OKS400 if you'd like. We will use the two brands mentioned as examples in this article, but of course there are also other forms and brands of lubricants available.

Let's Take a Closer Look at the Lubricant WD-40

If you take a closer look at the composition of WD-40, it quickly becomes clear that it is not necessarily the best way to keep the bearing lubricated without affecting the friction. This is due to the fact that WD-40 is referred to as a "penetrating oil".

In detail, this means that the lubrication can penetrate into cavities, mix with dirt and dust particles, and bring them to the surface. In addition, due to its thin consistency, it is not suitable as a long-term option.

Does the Use of WD-40 or Similar Lubricants Influence the Performance of the igus® Plastic Thread?

In order to get the exact answers to such questions, it is essential that we consult chemical tables in order to make the effects of WD-40 on iglide® materials clear. A 100% resistance of the iglide® materials depending on the type of contamination and the lubricant cannot be guaranteed.

Also, at this point we need to consider durability and wear and tear as two separate issues. As a rule, our materials are resistant to such oil-based lubricants, but that does not mean that they do not affect the screw nut.

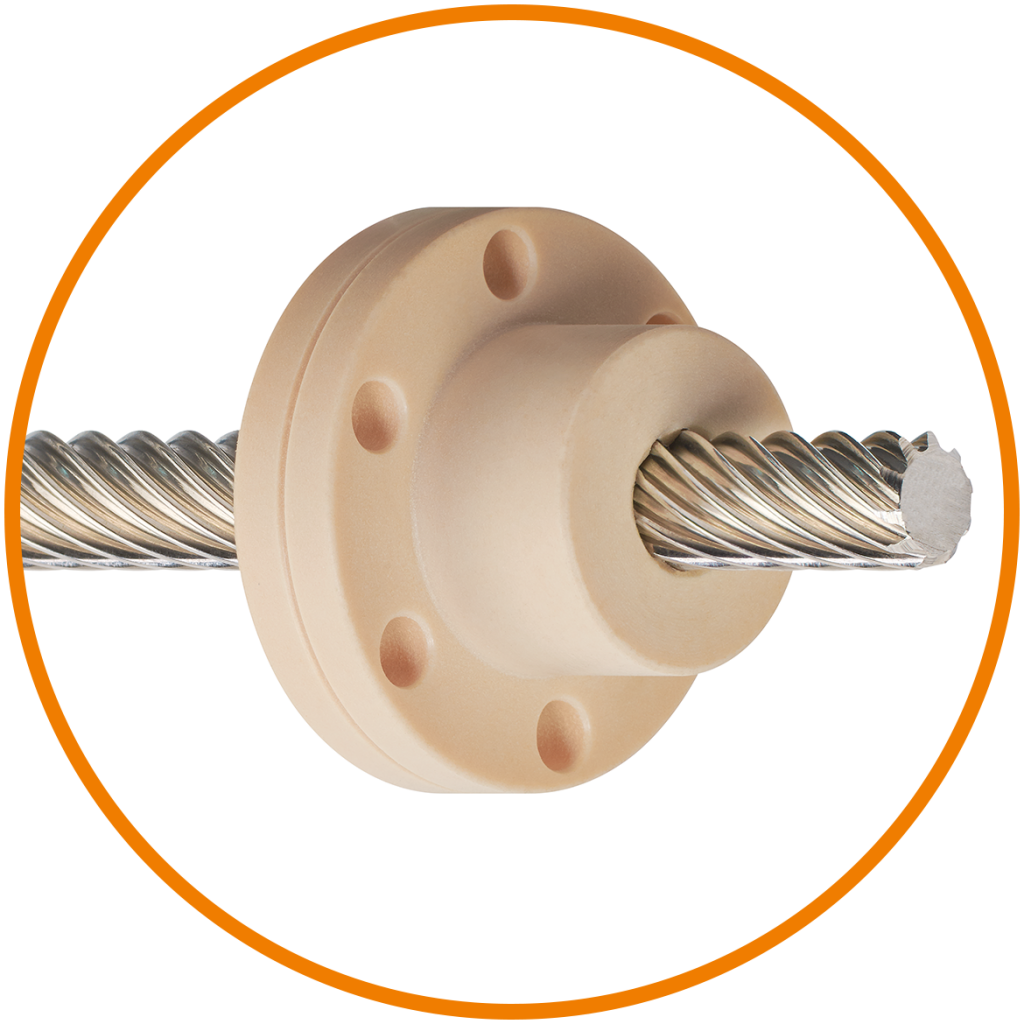

Why does the igus® plastic thread not have to be lubricated?

Our thread systems have been developed for maintenance-free, dry-running operation. Basically, a lubricated thread system should not be compared one-to-one with a dry-running system. Due to the external lubrication, the coefficient of friction is lower compared to a dry running thread system. However, the lubricant also causes high maintenance requirements and additional costs, which are often not taken into account.

In justified cases, however, an external lubrication of iglide® threaded nuts can be considered to reduce the coefficient of friction or to increase the speed without generating noise. However, one of our experts should always be consulted as to whether this really makes sense for your application.

As a general rule of thumb, do not lubricate in an abrasive environment -> "emery paste"

Another type of lubrication is initial lubrication. This is particularly conceivable for better running-in behavior. After the lubricant has been used up, there is almost linear wear.

iglide® plastics, on the other hand, have no lubricating film and no reservoir of grease that is used up. The homogeneous material structure of the threaded nuts ensures largely linear wear without surprises or maintenance intervals that have to be observed. Our materials are also characterized by their other special properties: their special composition makes them extremely wear-resistant and resilient. Due to the self-lubricating effect, the threaded nuts are 100% dry-running and maintenance-free. Particles such as dust and fibers can therefore adhere to the screw drives much more poorly. In dirty environments, this leads to a significant increase in service life compared to conventional, lubricated materials.

In conclusion, it can be said that the dryspin® lead screw nuts are resistant to most commercially available lubricants. However, there could well be increased, but also less wear. If you really want to lubricate externally, lithium saponified, mineral oil-based greases are best suited.

Use in Various Industries

Due to the advantages mentioned above, the dryspin® lead screw drives can also be used in special industries. In medicine or pharmaceutical technology, for example, it is mandatory that the installed products are absolutely clean, hygienic and very easy to clean. In very dirty environments, on the other hand, it is important that no dirt particles stick to the threaded nut or thread. This has a negative effect on wear and tear and running behavior.

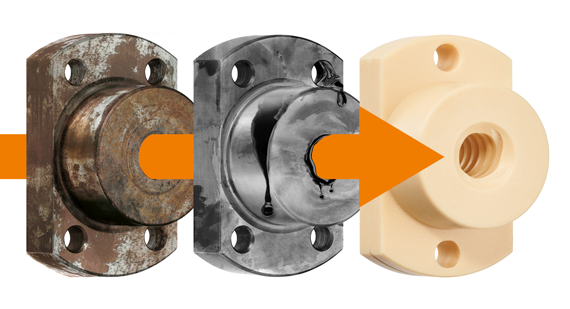

Our Plastic Threaded Nuts Compared to the Metal Solution

Metal thread systems require regular lubrication. Without the right lubrication, they will begin to corrode after a short time. To prevent this, corresponding downtimes for maintenance intervals are essential. The absolute freedom from lubrication and maintenance of our plastic threaded nuts also solves the problem here and offers a successful alternative to metal screw drives. Replacing the screw drives can improve the technology and reduce costs.

Visit our webpage to learn more about dryspin® lead screws and buts, or contact an igus® expert with any questions.