Testing bolts and bearings for construction machinery: Hardox® and iglide®

This article originally appeared on https://blog.igus.eu/bolts-and-bearings-for-construction-machinery-under-test-hardox-and-iglidur/

The Hardox® wear plates brand is frequently found in commercial vehicles and construction machinery where steel surfaces have to withstand the most severe stresses. From the loading area of dump trucks to the bucket of wheel loaders, Hardox® wear plates reliably protect against wear. For this reason, shafts and bolts made of Hardox® are obvious counterparts for iglide® plain bearings, which can show off their maintenance-free, dry-operating properties and high mechanical strength in construction machinery and commercial vehicles.

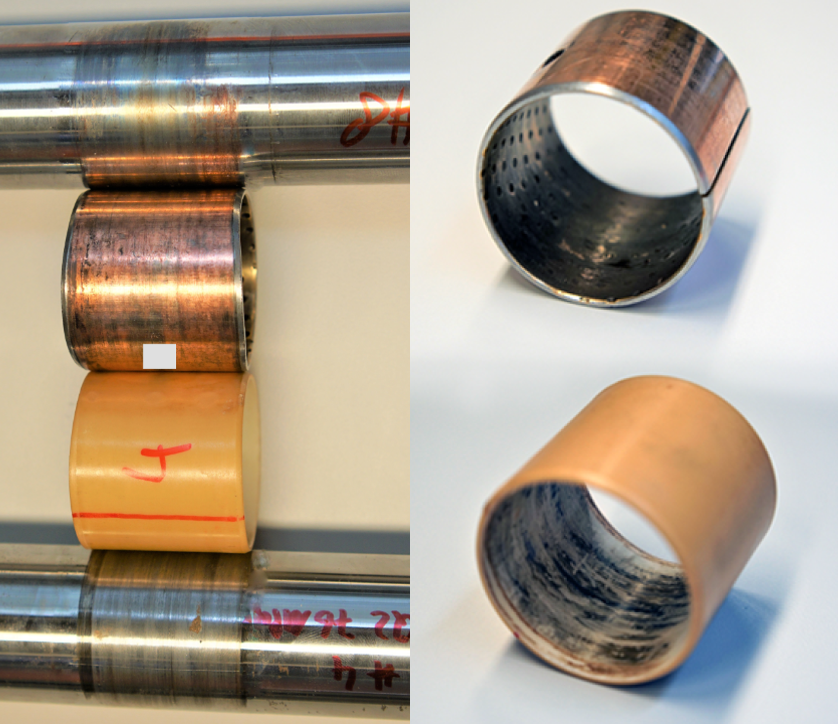

Since different pairs of plain bearings and bolts can differ greatly in terms of the wear resistance of the surfaces concerned, we subjected bolts made of Hardox® and bushings made of iglide® to real-world tests.

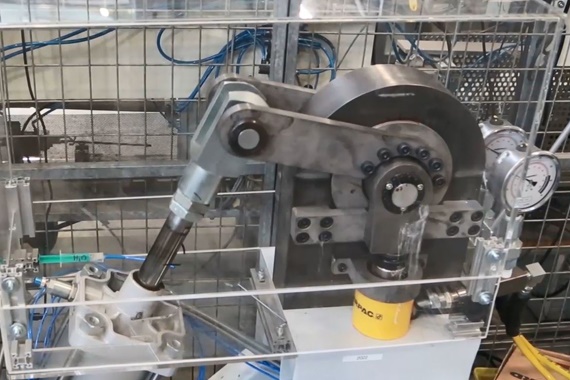

The heavy-duty test

To compare the service life, bronze bearings with initial lubrication were tested on bearing bolts made of Hardox® 400 in addition to slide bearings made of iglide® Q2. The test was carried out on the igus heavy-duty test stand. For this purpose, the bushings are pressed into a test fixture and subjected to a load of 76MPa pivoting and “tumbling” on the bolt to be tested. The pivoting angle here is 50° and is traversed at a speed of 0.01m/s. The aim was to achieve a cycle number of 45,000 in order to subsequently measure the resulting wall thickness loss as wear. Finally, the wear rate per km run can be calculated from this wall thickness loss.

The result

While the test with the solid bronze bushing had to be prematurely terminated after 10,000 cycles due to the high wear, the iglide Q2 bushing went through the full 45,000 cycles. After these 45,000 cycles, a wall thickness loss of 120µm could be measured at the bushing for the Hardox® 400 and iglide Q2 pairing. This corresponds to a wear rate of 73µm. In contrast, the bronze bushing already showed a wall thickness loss of 207µm after premature break-off after 10,000 cycles, corresponding to a wear rate of 559µm/km.

Conclusion

The combination of Hardox® 400 bolts with iglide Q2 bushings proved to be very advantageous and wear-resistant in the conducted test. The required service life of 45,000 cycles was completed with a good result and without significant damage to the treads.

Do you have questions about bearings in construction machinery applications? Contact an expert today, or call us at 800-521-2747.