Polymer Ball Bearings Withstand Extreme Heat in Pellet Stove

Plastics and hot temperatures in ovens can coexist, as the following application example from Koppe shows. Self-lubricating polymer ball bearings from igus® are successfully used in its pellet stoves for private households. The way the stoves work is ingenious, as the pellets burn without electricity thanks to a mechanical drive unit. The polymer ball bearings in the engine ensure long running times and smooth operation .

Plastics and hot temperatures in ovens can coexist, as the following application example from Koppe shows. Self-lubricating polymer ball bearings from igus® are successfully used in its pellet stoves for private households. The way the stoves work is ingenious, as the pellets burn without electricity thanks to a mechanical drive unit. The polymer ball bearings in the engine ensure long running times and smooth operation .

Polymer Ball Bearings for Pellet Stoves

In 2012, the Koppe company decided to bring a pellet stove to market. The issue of sustainability played a major role, as alternative energy sources should not result in any compromises in terms of mileage. A mechanical drive unit transports the wood pellets into the combustion chamber without electricity. The burning time is around 24 hours with a heating output of 10 kW. The company was looking for a bearing for the drive mechanism that could withstand the adverse conditions.

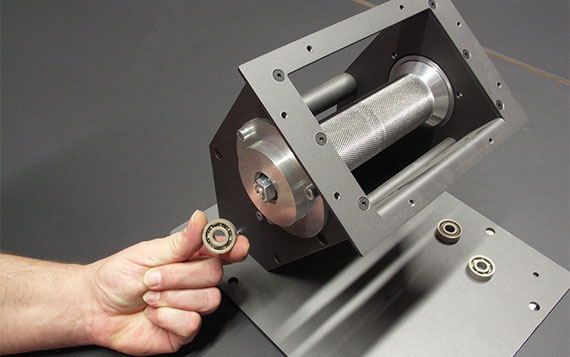

igus® quickly moved into action with its xiros® plastic ball bearings. In the mechanical drive unit, two xiros® ball bearings are now used, which impress with their stability. Where metal ball bearings quickly reach their limits, polymer ball bearings made from in-house materials solve many applications without lubrication and maintenance successfully.

The developments by the Koppe company resulted in Gravity, a pellet stove that combines the convenience of a conventional wood stove and the convenience of pellet technology. With an efficiency of over 80 percent, it is the first furnace of its kind to function smoothly using this system.

Differences From a Classic Stove

The major difference between classic and pellet stoves is the movement within the interior. A cylinder sitting on a roller transports the pellets from a storage container into the combustion chamber. The self-lubricating, maintenance-free xiros® ball bearings are used on the left and right of the roller. The temperature resistance comes from the material xirodur A500. This particular variant of the material allows for even short-term high temperature applications up to 599°F. In addition, the ball bearings are shockproof and guarantee long-term, smooth-running operation due to the fact that lubricants are not used. Metal ball bearings had no chance in comparison. Immediate seizure and high volume during operation were quick exclusion criteria.

Visit our webpage to learn more about xiros® ball bearings, or contact our xiros Product Specialist .