How to assemble a spindle motor

In this blog post, you'll learn what an igus® spindle motor is, how they work, and how to assemble one. Let's get started.

What Is a Spindle Motor?

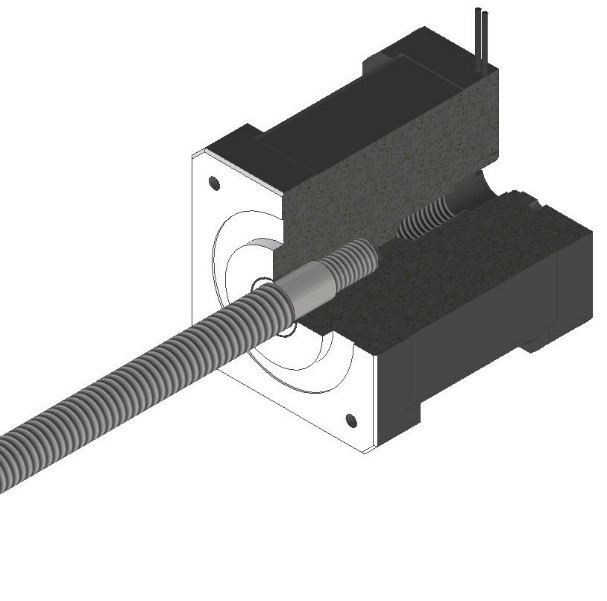

In its simplest form, an igus® spindle motor consists of a spindle and a motor (pictured right). To drive something, usually a motor is needed.

The design of the motor is a stepper motor with a hollow shaft. These motors are specially designed to absorb axial forces. Our NEMA23 spindle motor, for example, can take up 500N axially. Conventional stepper motors would be damaged by this axial load. In the hollow shaft there is a holder for our spindles so that they can be screwed and glued. This connection is so powerful that it can only be released with a special tool and a specially developed process. Please do not try it yourself, the motor will most likely be damaged.

The motor can also be equipped with an encoder and/or an industrial M8 connector. The spindle is specially machined for this motor so that the thread starts directly from the motor flange. This means that there is no loss of stroke.

Set the Correct Spindle Straightness

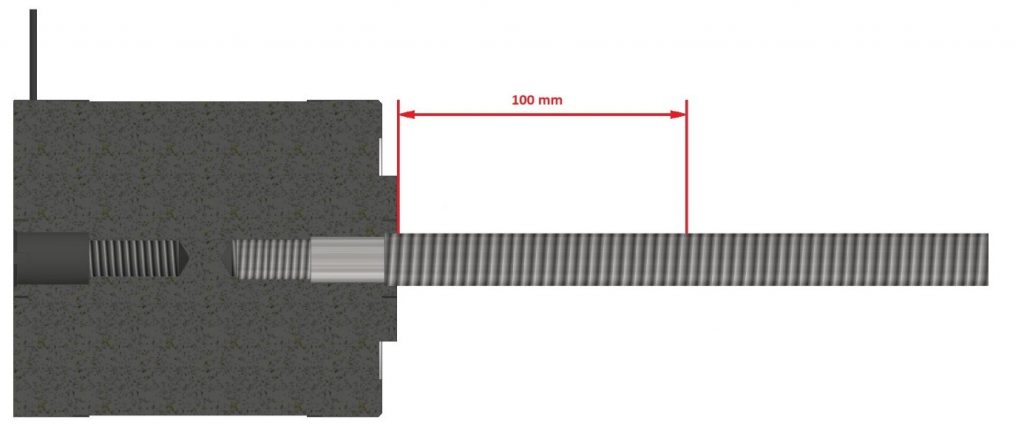

As soon as the spindle has been inserted into the motor, the spindle is straightened. Here we differentiate between two different spindle motor precision classes:

- SMP 0.2 concentricity of 0.2 mm measured from 100 mm of the motor flange

- SMP u undirected without definition

Usually the SMP 0.2 is sufficient, but we are currently developing processes to be able to guarantee even better concentricity. For very cost-sensitive applications, the SMP u can also be used to save on the last dollar.

Find the Correct Spindle Length

The definition of the spindle length for motor spindles is a bit tricky, but easy to understand:

- Spindle length = total length including mounting pin and shoulder

- Unsupported spindle length = spindle length from the motor flange without mounting spigot and shoulder

- Stroke = unsupported spindle length minus the length of the nut

In principle, all igus® spindles can be married to the motors, but - as always in mechanical engineering - common sense should be used. 40 mm spindle with Nema11 (0.12 Nm) certainly looks cool, but nothing more. Since the spindles have to be specially machined, we have a defined number of spindle geometries in stock. These are cut to length as required. You can find an overview of the available spindles online.

Visit our webpage to learn about our dryspin® lead screws and nuts or to use our lead screw configurator. You can also check out our motors page here, and contact an igus® expert if you have any questions.