Hidden (And Some Not So Hidden) Ways Linear Plain Bearings Can Save Cost In The Long Run

We often talk about how much more cost-effective linear plain bearings are compared to linear ball bearing systems. This is mainly due to the different techniques that are used within the manufacturing process of the parts. In this post, we'll be discussing linear plain bearings that are injection-molded, rapidly and repeatedly, producing thousands upon thousands of consistent, high quality parts. However, there are other reasons and considerations that come into play when discussing how these bearings save cost for the OEM they are supplied to, as well as the end user.

Materials & Processes

We are already aware that we are discussing plastic plain linear bearings that are injection molded, so we are going to discuss the other materials involved within a linear bearing assembly besides just the bearing liner itself.

Shafting and Guide Rails

Polymer plain linear bearings do not require the same hardened steel or stainless shafting (although they perform quite well on those materials as well) as ball bearings do, since they are perfectly suited to slide on less costly materials. By far, the most common guiding partner for a plastic bearing is aluminum, so many of the profile-type series use aluminum extrusions as the basis of the guiding rail. Extrusions are also a great way to save on costs compared to centerless grinding or other machining processes required for linear ball bearing guides. The aluminum itself also offers some less obvious cost advantages:

- Machining costs: Aluminum is significantly easier to machine than hardened steel for those customers who are looking to add custom holes, slots, or locating features. In fact, it is very common for many of the machine shops I work with to no-quote the machining of hardened steel, but they love to machine into aluminum since it is softer and easier to work with.

- Transportation costs: Linear plain bearing systems can offer up to 70% weight savings vs. ball bearing systems. The cost of moving these parts from one manufacturing facility to another are considerable, especially if the parts are going by air.

Housing Materials

Due to the geometry of injection molded plastics, as well as the fact that they do not require any special fittings or lines for oil or grease—since they are self-lubricating—there is more flexibility in regard to how a customer could mount a linear plain bearing. First off, it is certainly possible to just drill a bore (to the correct tolerance of course) and press-fit a plastic bushing, although circlips are recommended for higher axial security. Press it in and you are done.

Ball bearings, however, require the extra machining to accept a grease fitting—this is not needed by a plastic plain linear bearing. Alternative pillow block housing materials also exist for plastic plain linear bearings. Linear ball bearings are usually sold in aluminum pillow blocks that have machined features, and require the grease fittings and circlips I just mentioned; or, in the case of profile ball bearings, they may have housings or carriages with other machined features and channels for the ball bearings to roll within. Plastic bearing liners are able to be clipped into low cost zinc housings significantly reducing the cost of the overall system (image of WJ200UM-01-10). In fact, some machines that use several ball bearings may require special machining throughout the equipment in order to pass grease lines, and may require extra equipment such as manifolds, or automated or gravity-fed oil administration systems. With plain linear bearings all of that goes away leaving a less costly BOM for the machine.

Zinc housing shown on WJ200UM-01-10 bearing

Maintenance costs

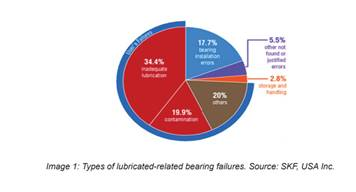

While the OEM of a machine or piece of equipment may not be strapped with the burden of maintaining the bearings after purchase, in the long run there is still a significant potential cost savings for the end user of the machine. With self-lubricating linear bearings, there is less downtime for scheduled maintenance since there is no need to worry about ever having to lubricate them. They also thrive within applications that are dirt or dust prone, such as agricultural or construction machinery, which can save on replacement costs. Another hidden benefit is that if they do wear out you can replace just the plastic bearing liner—since they do not damage the shaft or guide rail when they fail, they can run on the existing shafting. In the right applications they can also be used to replace ball bearings on existing applications that had failed, even if the shafting is not 100% perfect!

We have a more extensive article about lubrication and the costs associated with it, which can be found here.

Environmental costs:

Here are four reasons to use environmentally friendly plastic bushings:

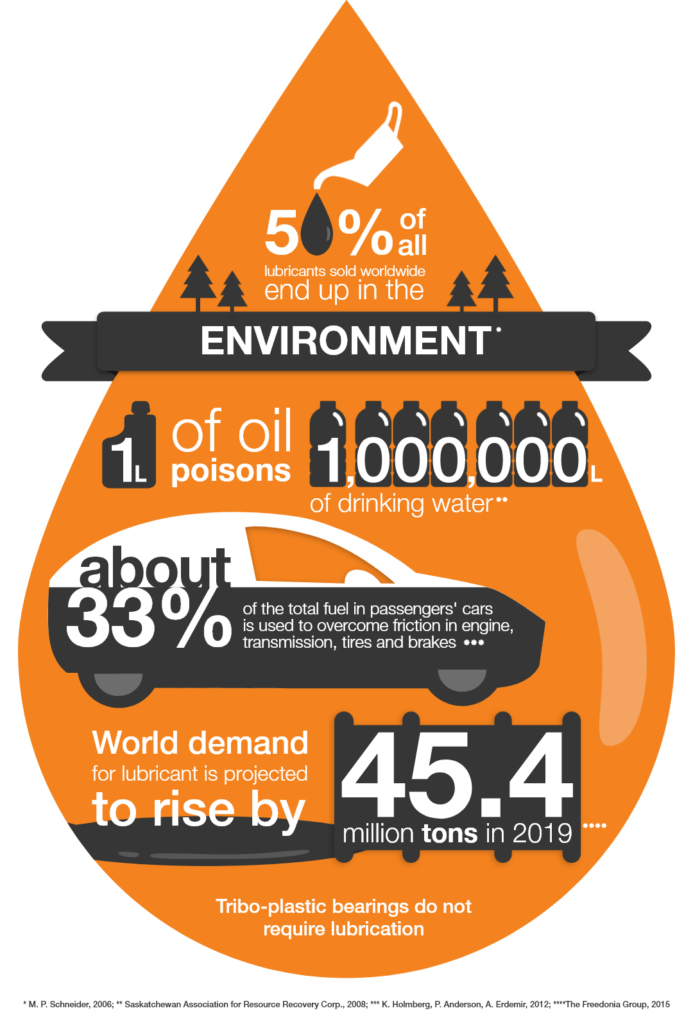

- Plastic linear bushings do not require lubrication, which keeps the environment cleaner. It is estimated that one billion gallons of industrial lubricants are consumed annually within the United States, and about 40 percent of that is released into the environment. Due to continual advances in tribologically-optimized plastic bearing technology, igus® is able to supply metal bearing alternatives that are more in line with environmental considerations for an increasing number of applications. Unlike metal or bronze bearings that require messy lubrication, every iglide® plastic bushing uses solid lubricants embedded inside millions of tiny chambers that cannot be pressed out. This means that the bearings do not require any oil or grease—so no contaminants are released into the environment.

- Plastic bearings are extremely lightweight, which helps reduce fuel consumption and carbon dioxide output. The reduced weight leads to lower masses and subsequently lower energy consumption.

- The high chemical resistance of plastic bearings is another positive ecological aspect. Metals often have to be coated using an environmentally unfriendly, high-energy zinc galvanizing bath to achieve this effect.

- Less energy is required to produce a plastic bearing compared to a metal bearing. For example, the energy from 15 liters of crude oil is necessary to produce 1 liter of aluminium and the energy from 11 liters of crude oil is necessary to produce 1 liter of steel. In comparison, it only takes 1 liter of crude oil to create 1 liter of plastic, and we expect this value to fall even further based on continuing breakthroughs in the field of vegetable-oil based plastics.

So, although I may be biased, I am positive that polymer linear bearing technology can offer you both a cost reduction and technical improvement when it comes to your machinery. The next time you are looking at using linear ball bearings, I encourage you to think again and give plastic linear guides some consideration. Here is a link to another blog that offers some insight as to when plastic plain bearings can be used, and when you should consider ball bearings—unfortunately 😊.